Elevate your epoxy projects with Solid Color Epoxy Pigment, a versatile and vibrant solution designed for a wide range of applications. This premium pigment allows you to transform dull surfaces into stunning displays of color, perfect for crafting beautiful floors, countertops, and art pieces. With a straightforward mix ratio, simply add one container of this brilliant pigment to 3 gallons of Part A epoxy, adjusting as needed to achieve your desired level of opacity.

The Solid Color Epoxy Pigment is specifically formulated to meet the demands of both professional and DIY enthusiasts. It excels in a variety of projects, making it an essential choice for flooring installations, including chip floors and as a base coat for metallic epoxies. The pigment successfully fills cut lines, creating a seamless finish that enhances the durability and visual appeal of your surfaces.

Coverage depends on the porosity of the concrete and application method: achieve a stunning spread of 400-800 square feet when using a roller and 200-300 square feet with a squeegee. Whether you’re upgrading a residential space or completing a commercial project, this pigment delivers consistent, high-quality results that enhance any environment.

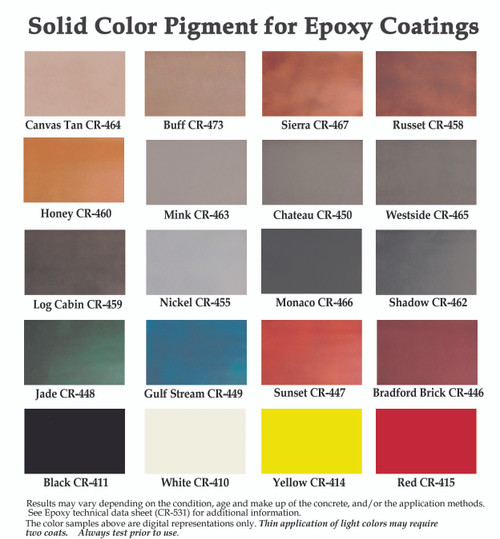

Available in an array of solid colors, Solid Color Epoxy Pigment invites you to unleash your creativity, enabling you to design mesmerizing patterns and unique textures. Perfect for decorative art projects, it allows artists and hobbyists to explore their talents while ensuring professional-grade finishes. Invest in Solid Color Epoxy Pigment today and bring your visions to life with color that lasts.

Click Here for PDF of Technical Data Sheet

Technical Data

Technical Data Sheet (TDS)

CONCRETE RESURRECTION Solid Color Pigment for Epoxy Coatings

**This product may only be used on fully cured concrete. Allow a minimum of 28-45 days of cure time (or until

a pH reading of 10.5 or less is achieved) after the concrete is poured to allow ample time for the concrete to

completely hydrate. It is recommended that a calcium chloride (or similar) moisture test be completed on any

floor prior to Inside Epoxy application.

Solid Color Epoxy Pigment is ideal for…..

Floors and counter tops

Base coat for metallic epoxy

Filling cut lines

Chip floors

Art projects

Coverage (varies based on concrete surface porosity and amount of material applied)

¾ Gallon Kit:

3 Gallon Kit:

Surface Preparation

100-200 sq ft Applied with Roller

50-75 sq ft Applied with Magic Trowel

400-800 sq ft Applied with Roller

200-300 sq ft Applied with Magic Trowel

A fine to medium shot blasting or the use of a diamond grinding machine to obtain a surface profile of a CSP -

3 to a CSP - 5 is suggested for ultimate adhesion.

A test should be made to determine that the concrete is dry; this can be done by placing a 48” x 48” plastic sheet

on the substrate and taping down the edges. If after 24 hours, the substrate is still dry below the plastic sheet,

then the substrate should be ready to coat. More advanced moisture testing kits should be used on floors with

suspected moisture problems.

Apply coating to a clean surface that is completely dry and free of oil, dirt, grime, wax, detergent or any

incompatible paint or coating.

Concrete must be completely dry prior to sealer application. It is strongly recommended that a surface probe

moisture meter be utilized to verify the surface is dry. After visually determining the concrete is dry, test a

minimum of 10 different areas of the concrete with the moisture meter. Pay special attention to cracks, control

joints, and slab edges.

Mixing Instructions

When mixing epoxy pigments, add the appropriate amount of pigment into the resin (part “A”) and mix

completely using a paint mixer on a low speed drill. When desired color is achieved, follow the directions

above for adding and mixing in the hardener (part ”B”). It is critical to have an exactly portioned mixture,

which has been prepackaged for you to eliminate any guesswork or measuring. After combining the two

components, use a paint mixer on a low speed drill for 2 minutes to completely mix the components. Be careful

to not whip air into the mixture, and be certain to scrape the sides and bottom of the can to combine all

molecules. Incomplete mixing or an off balance mixture will result in a coating that will remain soft.

Application Recommendations

The epoxy can be applied at a rate of 3 to 8 mils thick, using a roller, squeegee or trowel within the usable pot

life time frame, as well as the recommended temperature and relative humidity guidelines listed in the

Technical Information section. If concrete conditions or aggressive mixing causes air entrapment, then an air

release roller tool should be used prior to the coating tacking off to remove the air entrapped in the coating. If

the material becomes thick while applying and sticking to the application tools , stop applying and discard the

mixed material. At this point it has reached the end of the usable pot life. While applying keep a wet edge to

prevent streaking. It is recommended to work in sections usually using control joints as dividers to ensure

proper application results. Do not allow to Puddle!

For a thicker build and bolder color pour contents out in a long trail for application. Spread with Notched

squeegee or gauge (wider squeegee is recommended), Spread product evenly over area. Flatten the poured out

trail into place, as it self-levels. Back roll with a 3/8” roller or mohair roller or smooth using a Magic Trowel,

speed squeegee or loop roller. (rollers should be premium quality with phenolic core and 18” wide is

recommended for larger areas)

Thinning -- Do not thin.

Finish Coat and Additional coats

Previously coated surfaces must be mechanically cleaned and abraded using a floor machine (buffer) with 80

mesh sanding screen prior to application to ensure adequate inner coat adhesion. Follow abrading with

vacuuming and wipe down with a micro-fiber cloth with denatured alcohol or acetone. For superior protection,

you may choose to apply a top coat of Concrete Resurrection Polyaspartic or High Gloss Urethane.

Please Note: Applying CR-531 Inside Acrylic outside of the suggested parameters may result in job failure. It

is always recommended to test the product in a small, inconspicuous area (on the same concrete substrate) for

desired results prior to application. Coverage rates may vary for all coatings and substrates depending on

porosity, density, texture etc.

Clean Up

Discard used consumable items such as roller pans, roller covers, brushes, etc.

Abrasion Resistance………………...………………......................28.1 mg loss

(Tabler Index, ASTM 4060-81, CS-17 Abrasion Wheel, 1000 gram load)

Gloss 60 ْْ .............................................................................................90-95

Flexibility (1/8” Mandrel)....................................................................................Pass

Hardness - Shore D......................................................................................82

Compressive Strength @ Yield (psi)………………………………………11,200

Tensile Strength (ASTM D638).................................................................6200

Elongation………………………………………………………………………...7%

Solids % Weight (Federal Spec. TTP-141B)...........................................................100%

Density lbs/Ga. (Federal Spec. TTP-141B)..............................................................9.32

VOC ……………………………………………………………< 5 grams per liter

Mix Ratio (a/b volume)..........................................................................................2 to 1

** 19.33# part A (2.0 gallon approximate) to 8.66# part B (1 gallons approximate)

Viscosity......................................................................................................400-600 cps

Pot Life...................................................................................................20 - 30 minutes

Dry Time-Set to Touch (50% R.H. @ 72 ْ F).............................................................6 - 8 hours

Dry Time-Recoat (50% R.H. @ 72 ْ F)..................................................................10 - 16 hours

Dry Time-Light Traffic (50% R.H. @ 72 ْ F)...........................................................14 - 18 hours

Dry Time-Full Cure (heavy traffic) (50% R.H. @ 72 ْ F)...............................................2 - 7days

Application temperature………………………………………………...55-90 degrees F

Storage and Shelf Life

Do not allow to freeze. Shelf life of unopened product is approximately one year.

10% Sodium Hydroxide…… ..E

Butanol………………..C

Xylene………………...C

1,1,1 trichloroethane…..B

Methanol >>………..…A

Gasoline………………C

Skydrol B-4…………...B

Ethylene Alcohol……...C

MEK…………………..A

Rating key: A - not recommended, B - 2 hour

term splash spill, C - 8 hour term splash spill,

D - 72 hour immersion, E - long term

immersion.

50% Sodium Hydroxide…… ..D

10% Sulfuric Acid…………....C

70% Sulfuric Acid>>……….A

5% Acetic Acid………………B

10% HCI (aq)…………………C

•• A chemical exposure test should always be

performed prior to application resistance to

ensure satisfactory results are obtainable.

Limitations

Air and substrate temperatures must be minimum 50F

Do not apply when air or surface temperature exceeds 90 degrees (F) or LAP marking / poor penetration /

bubbling may result. Do not apply to wet or damp concrete, moisture will inhibit penetration of the sealer and

cause improper curing, flaking or lifting of the sealer. Do not apply if dew may condense on the surface before

the sealer has cured. Allow for extended curing times during cold weather / high humidity.

Moisture Vapor Emissions/Alkalinity Precautions

All interior concrete floors not poured over an effective moisture vapor barrier/inhibitor are subject to possible

moisture vapor transmission and related high levels of alkalinity that may lead to blistering and failure of the

coating system. It is the coating applicator’s responsibility to conduct calcium chloride and relative humidity

probe testing to determine if excessive levels of vapor emissions or alkalinity are present before applying any

coatings.

Warranty

The Manufacturer and/or the Seller warrants that if any goods supplied prove defective in workmanship or

material, that Manufacturer and/or Seller shall replace them or refund the purchase price. This warranty is made

in lieu of any and all other warranties expressed or implied. Before application, the User shall determine the

suitability of the product for his intended use and User assumes all risks and liabilities whatsoever in connection

therewith. Under no circumstances shall the Manufacturer and/or Seller be liable for incidental, consequential or

other damages for alleged negligence, breach of warranty, or strict liability arising out of use or handling of this

product. The sole liability of Manufacturer and/or Seller for any claims arising out of the use or sale of the

product shall be for the User's purchase price. Any claim of defective product must be received in writing

within one (1) year from date of shipment.

Safety

Do not breathe vapors. When using in confined or limited ventilation areas, use appropriate organic vapor

respirator to protect against methyl amine vapors. Avoid contact with skin; wear protective gloves and clothing.

Always use eye protection such as goggles, face shield or safety glasses. Read Material Safety Data Sheet

before using.

First Aid

Eye Contact: Immediately flush eyes with plenty of water for at least 15 minutes while holding eyelids open.

Seek medical attention.

Skin Contact: Immediately remove contaminated clothing. Wipe excess from skin and wash with soap and

water. Seek medical attention if irritation persists.

Inhalation: Remove person to fresh air and provide oxygen if breathing is difficult. Seek medical attention.

Slip and Fall Precautions

OSHA and the American Disabilities Act (ADA) have now set enforceable standards for slip-resistance on

pedestrian surfaces. The current coefficient of friction required by ADA is .6 on level surfaces and .8 on ramps.

Engrave-A-Crete, inc. recommends the use of angular slip-resistant aggregate in all coatings or flooring systems

that may be exposed to wet, oily or greasy conditions. It is the contractor and end users’ responsibility to

provide a flooring system that meets current safety standards. Engrave-A-Crete, Inc. or its sales agents will not

be responsible for injury incurred in a slip and fall accident.