All About Concrete Stain

Plain concrete becomes jaw-dropping beautiful with the application of Concrete Resurrection stains and sealers.

Available in a wide range of colors, our stains are manufactured in the USA in-house by chemical specialists to assure you a consistent, high-quality product that gives good results every time.

Our staining experts are on hand for continued customer support.

For technical support contact us at 800-884-2114 or email info@concreteresurrection.com

We offer 3 types of concrete stain to choose from depending on your color specifications and project.

Reactive Acid Stain (RAC)

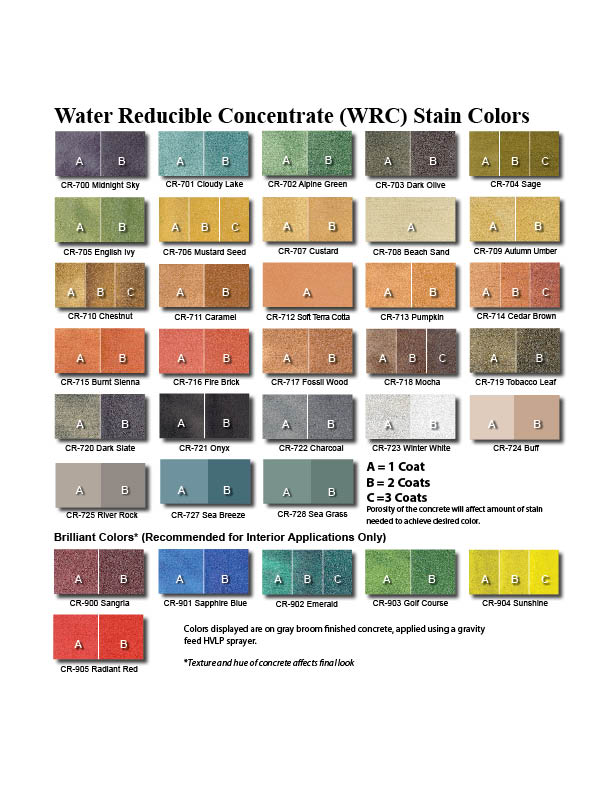

Water Reducible Concentrate (WRC)

Ten Second Color/Speed Color (TSC)

You can learn more about each of these stains below.

Reactive Acid Chemical (RAC) Stain

- Physically reacts with minerals in concrete to change the color of the concrete. This will not cover any blemishes in your concrete as the concrete itself changes color.

- RAC Stain color varies from slab to slab - No two slabs will stain the same.

- RAC stain comes in earth tones and will look dull without a sealer applied to it.

- Repairs to the concrete, such as filled cracks or divots, tend to color differently from the area around them.

- The RAC color chart gives you a representation of the color you will get, but if you are very color specific in what you want (for instance trying to exactly match an existing floor or counter top) then RAC Stain is not the best choice.

- Always test RAC stain in an inconspicuous area prior to applying to the entire surface.

- RAC Stain can be used on exterior and well- ventilated interior concrete.

- Do NOT ETCH concrete that is porous and you plan to use an acid stain on. Etching will destroy the minerals you need for the stain to react with to achieve color.

Application Instructions

Step 1: Slab needs to be clean and porous (allows water to soak in). (See Tech Data for proper prep)

Step 2: Apply acid stain with an all plastic sprayer heavy enough for the stain to saturate the concrete short of puddling. For a lighter shade, RAC stain may be diluted with up to 4 parts water or Concrete Resurrection Color Extender which keeps the acidity in your stain up for better results.

Step 3: Allow acid stain to react with concrete 4-5 hours to achieve maximum coloring effects. The residue that is left is what has come to the surface during this time. This is not your color!

Step 4: Wash and neutralize concrete to remove residue. You can neutralize with Concrete Resurrection Neutralizer. You will know all residue has been removed when water comes off clear or you can wipe a cloth over it and have little to no color on it. At this point, how it looks wet is approximately how it would look sealed. The sealer you choose will effect the final look.

Step 5: If you are satisfied with your color, allow to dry completely then apply sealer.

Coverage–Amount of square footage stained per gallon varies with the surface texture of the concrete, temperature of the concrete and ambient conditions. Average coverage rate is 100-200 sq ft per gallon. Can be diluted with up to 4 parts water for a lighter coverage. Color extender can be used to keep the acidity in the stain up.

Please review Technical Data Sheet for more specific instructions. It can be found under the header Technical Data Sheets.

_____________________________________

Water Based Stain

Water Reducible Concentrate (WRC) Stain is an easy to use pigmented waterborne stain that bonds tenaciously to the open pores of the concrete. It is very color accurate (what you see is what you get.) WRC Stain colors can be blended for variations from the standard colors and faux finished for unique looks. The more water you add the more translucent it becomes so it will not look like a painted surface. This stain is designed to have highs and lows - but you can achieve a solid color with multiple coats.

Coverage–

- WRC Stain always requires dilution with water.

- Its minimum dilution is 4 parts water to 1 part stain. Maximum dilution is 8 parts water to 1 part stain. The more water you add the more translucent the stain will be.

- At a 4:1 dilution rate a 32 oz bottle yields 1.25 gallons of ready to use stain and covers approx. 250 sq ft. (8z bottle covers 62.5sq ft) - Coverage will vary based on how heavy you apply it and how porous your concrete is.

- At a 8:1 dilution rate a 32oz bottle yields 2.25 gallons of ready to use stain covering about 500 sq ft. (8z bottle covers 250sq ft) - Coverage will vary based on how heavy you apply it and how porous your concrete is.

- WRC can be applied in multiple coats for a solid, opaque color.

IT IS ESSENTIAL THAT YOUR CONCRETE BE POROUS FOR WRC TO BOND PROPERLY.

IF YOU POUR 1/4 CUP WATER ON YOUR CONCRETE YOU SHOULD SEE THE CONCRETE CHANGE COLOR/WATER ABSORB WITHIN 15-20 SECONDS. If not, you will need to prepare your concrete before application - you can learn more about that in the technical data sheet.

Application Instructions:

Step 1: Concrete must be very clean and porous. (Water must readily soak in and concrete should feel similar to 120 grit sandpaper.)

Step 2: WRC can be diluted for a more translucent effect.

Step 3: Apply WRC Stain with a gravity feed HVLP sprayer (preferred), pressure pot HVLP sprayer, airless sprayer, pump sprayer, cotton rag, natural sponge (sea sponge), manufactured sponge or brush (bristle or foam).

Step 4: Allow to dry completely and apply sealer.

Please review Technical Data Sheet for more specific instructions. It can be found under the header Technical Data Sheets.

_________________________________________________

Ten-Second Color And Active Elements Dyes

Ten Second Color™ (TSC) and Active Elements Speed Color (AE) are penetrating stains to color concrete and other cementitious surfaces. When properly applied (with a sprayer typically), they create beautifully mottled effects similar to an acid stain. TSC and AE are translucent dyes that are UV Stable. Colors can be combined into countless variations and hues, or layered for unique effects. Simply add required amount of acetone and go! -

Coverage– One quart Dye covers up to 150 sq ft. Coverage variations depend on concrete surface porosity and amount of material applied.

Application Instructions:

Step 1: Concrete must be very clean, dry and porous. (Water must readily soak in and concrete should feel similar to 120 grit sandpaper.)

Step 2: Apply Dye with a cone tip pump sprayer that is compatible with acetone. Dye can also be applied with a brush, roller or HVLP spray equipment.

Step 3: Allow to dry completely and apply sealer.

Click here for complete TDS instructions