Nature's Essence Matte Concrete and Paver Sealer

🌿 Product Overview

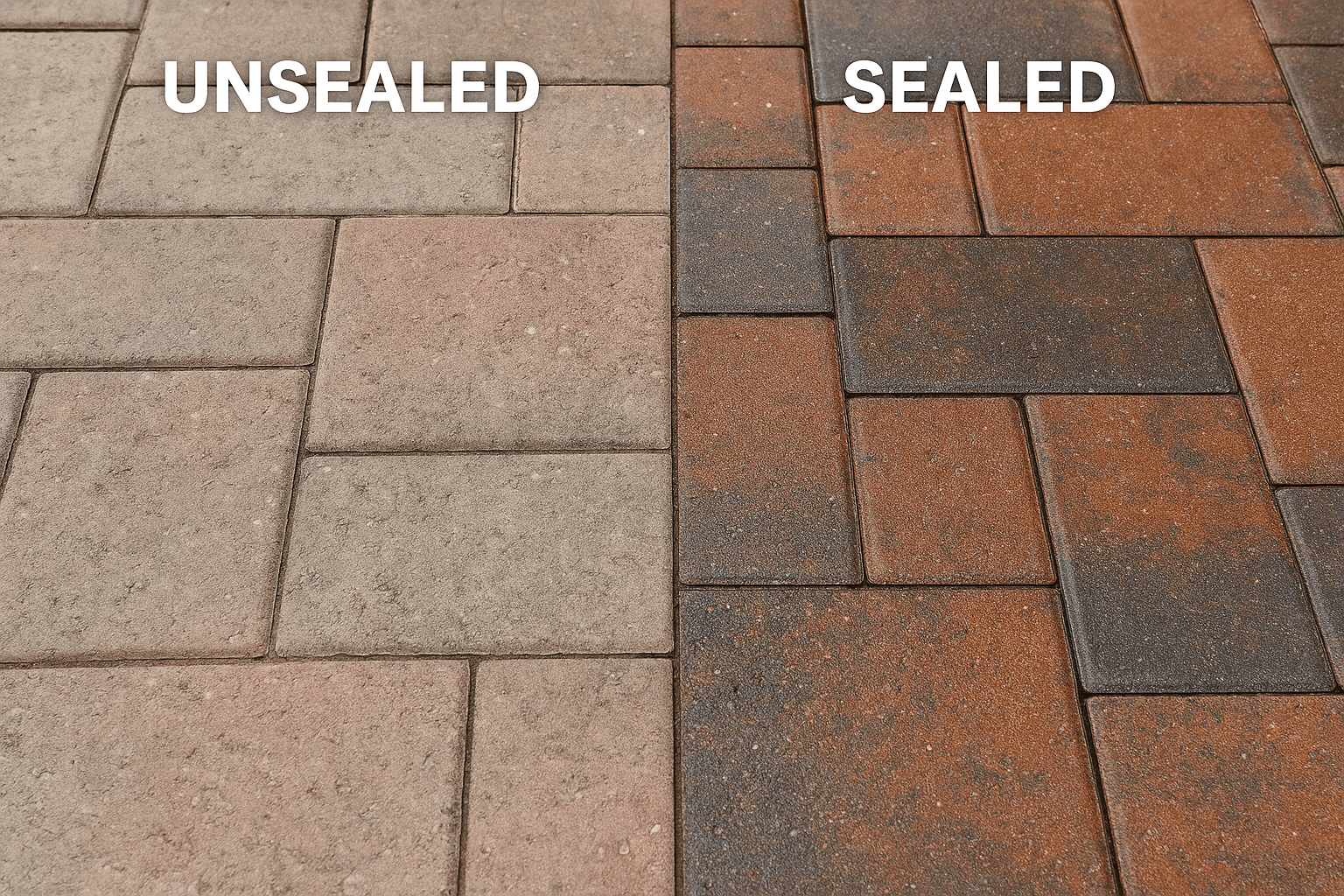

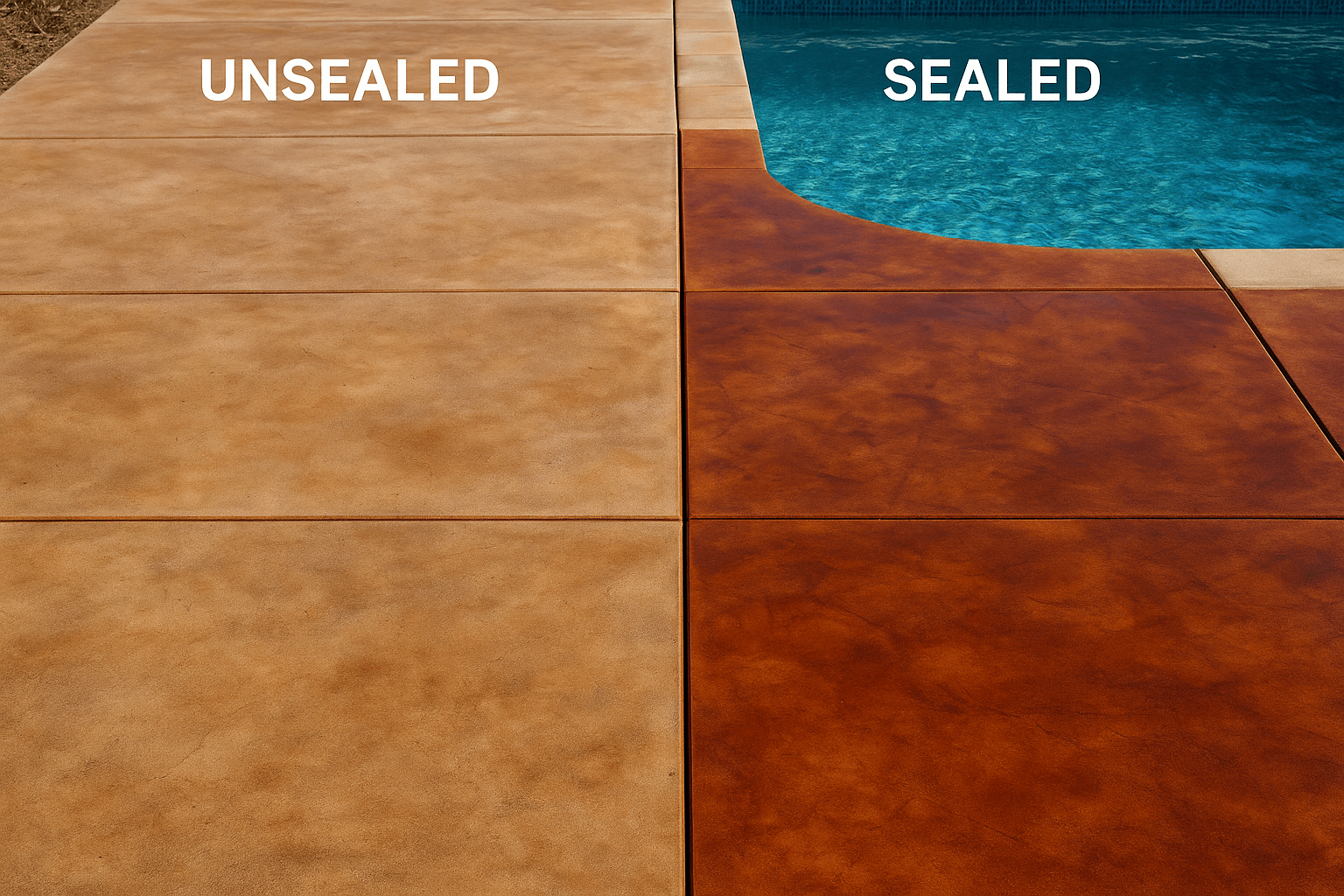

Concrete Resurrection’s Nature’s Essence Matte Paver and Concrete Sealer is a high-performance, solvent-based silicone water repellent designed to enhance color, preserve texture, and maintain surface safety across a wide range of porous materials. This clear, penetrating formula protects against water intrusion while enriching the natural tones of concrete, pavers, brick, stone, and cementitious overlays.

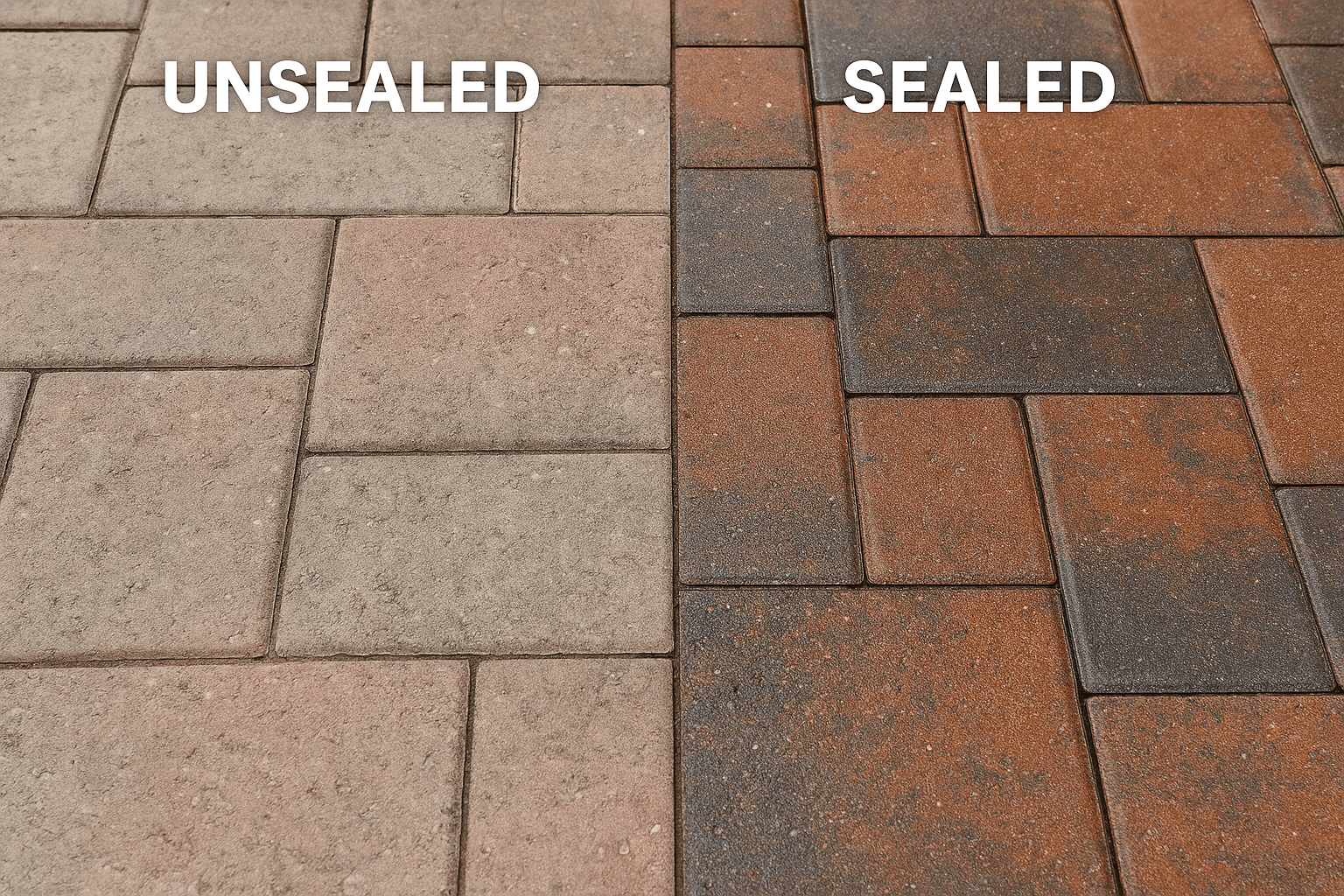

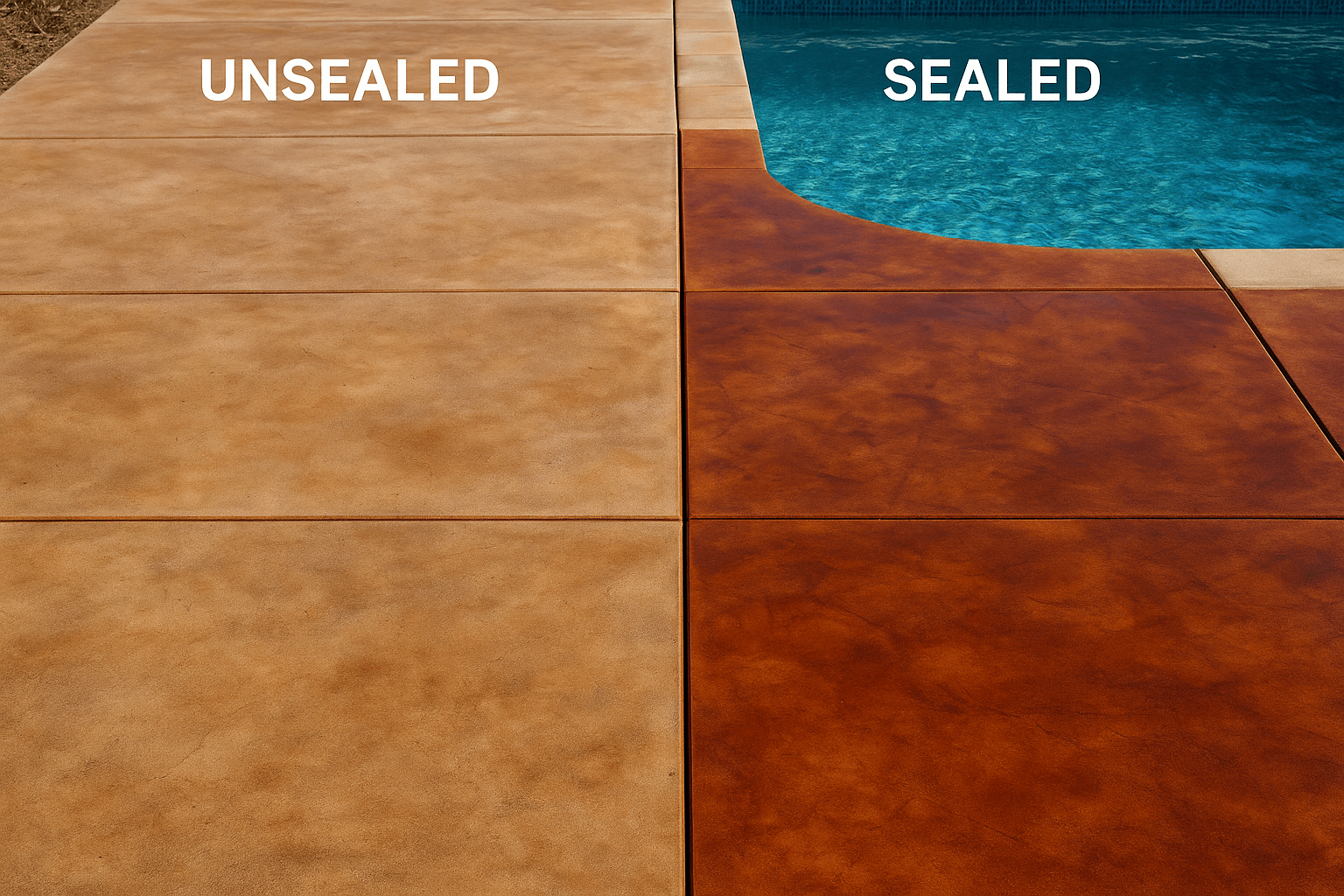

It deepens color without adding gloss or altering surface texture. Whether you're sealing a decorative patio, walkway, or vertical surface, this sealer delivers a non-slip, breathable barrier that protects and elevates your surface—without the shine.

Note: For use only on unstained, acid-stained, or integral color concrete. Not compatible with topical stains, dyes, or previously sealed surfaces.

🔍 Key Benefits

- Matte Finish: Enhances surface color with a soft, natural look—no gloss, no shine

- Color Enrichment: Enriches the natural tones of concrete, pavers, brick, stone, and cementitious overlays.

- Non-Slip & Texture-Safe: Maintains original surface grip and feel—no film, no slickness

- Water Repellent: Guards against moisture, stains, cracking, and freeze-thaw damage

- Breathable Barrier: Allows vapor transmission while sealing out water

- Durable Protection: Chemically bonds within the substrate for long-lasting performance

- Versatile Use: Ideal for patios, walkways, driveways, vertical surfaces, and commercial floors—indoors or out

🧱 Recommended Surfaces

- Unstained Concrete

- Acid-Stained Concrete

- Integral Color Concrete

- Brick & Block

- Pavers

- Unglazed Tile

- Cementitious Overlays

- Natural & Decorative Stone

🛠️ Application Guidelines

- Type: Solvent-based silicone impregnating sealer

- Finish: Clear, matte

- Coverage: Varies by porosity; typically 100–300 sq ft per gallon

- Dry Time: Surface dry in 1–2 hours; full cure in 24–48 hours

- Tools: Low-pressure sprayer, roller, or brush

- Clean-Up: Use appropriate solvent per manufacturer’s instructions

- Surface Compatibility: Only apply to unstained, acid-stained, or integral color concrete. Do not use on surfaces treated with topical stains, dyes, or incompatible sealers.

⚠️ Performance Notes

- Not intended to create a glossy or wet-look finish

- Test on a small area before full application

- Do not apply to non-porous or previously sealed surfaces without proper prep

📦 Packaging

- Available in 1-gallon and 5-gallon containers

- Shelf life: 12 months (unopened, stored in cool, dry conditions)

🌎 Sustainability & Safety

- VOC-compliant in most regions

- Always wear protective gear during application

- Dispose of unused product and containers responsibly

First Coat: 100 - 300 ft2 per gallon. Coverage varies with the surface texture of the concrete, temperature of the concrete, and ambient conditions.

🧼 Surface Preparation & Mixing Instructions

Before beginning surface preparation, take care to protect all non-masonry surfaces and surrounding areas. Shield people, vehicles, landscaping, and property from potential exposure to the product, including wind drift, splash, residue, and fumes. It is also recommended to redirect or block pedestrian and vehicle traffic during application.

Thorough surface preparation is essential for optimal performance. All surfaces must be clean, dry, and absorbent. Remove any oils, dirt, dust, grease, curing compounds, previous coatings, efflorescence, and laitance. Excess moisture can inhibit penetration and compromise the longevity and effectiveness of the sealer.

Temperature matters. Air and surface temperatures must be at least 40°F during application and for a minimum of 8 hours afterward. If freezing conditions occurred prior to application, allow the substrate to fully thaw before proceeding. Failure to do so may result in reduced protective performance. Avoid applying when air or surface temperatures exceed 80°F.

🧱 Recommended Surfaces

- Unstained Concrete

- Acid-Stained Concrete

- Integral Color Concrete

- Brick & Block

- Pavers

- Unglazed Tile

- Cementitious Overlays

- Natural & Decorative Stone

🧪 Mixing Instructions

Stir Nature’s Essence Matte Concrete and Paver Sealer thoroughly before use.

DO NOT THIN. Apply as-is for best results.

🧪 APPLICATION INSTRUCTIONS

Proper equipment should be used when applying Nature’s Essence Matte Concrete and Paver Sealer. A brush, roller, or low-pressure sprayer (maximum 20 psi) is recommended. When using a sprayer, adjust to achieve a wet, even stream—avoid atomization. Ensure all containers used for mixing or handling are clean, debris-free, and uncontaminated.

Before applying, read the full technical data sheet for proper surface preparation, application steps, and safety guidelines. Always test the substrate prior to full application to confirm desired results. Allow the test area to dry completely before final inspection and approval.

🧱 HORIZONTAL SURFACES

Apply Nature’s Essence Matte Concrete and Paver Sealer at a rate of 100–300 sq. ft. per gallon, depending on surface type and porosity. Broom out any puddles until the product fully penetrates. Reapply a second coat once the sheen from the first coat dissipates—less material may be needed for the second coat. Again, broom out any puddles to ensure full absorption. This is a wet-on-wet application.

- Dry to touch: ~1 hour

- Protect from weather: Minimum 24 hours

- Water & oil repellency: Begins within 24 hours

- Neutral pH surfaces: May require several days for full repellency

🧱 VERTICAL SURFACES

For best results, apply Nature’s Essence Matte Concrete and Paver Sealer wet-on-wet at 100–300 sq. ft. per gallon to a dry, absorbent surface. When spraying, saturate from the bottom up, allowing a 4"–8" rundown below the spray point. Let the first coat penetrate for 5–10 minutes, then reapply—less material is typically needed for the second coat.

When using a brush or roller, saturate the surface evenly and allow 5–10 minutes for penetration. Brush out any heavy runs or drips that show signs of poor absorption. A second coat is recommended for maximum protection.

⚠️ IMPORTANT NOTES

- Always test in a small, inconspicuous area on the same substrate before full application.

- Coverage rates vary based on porosity, density, and texture.

- Spray applications may yield extended coverage but reduced material deposition—performance may be affected.

Let me know if you'd like this formatted for a label, spec sheet, or installer guide!

- Drying Time Dry to touch: 30-60 minutes

- Dry Time Foot Traffic: 4-8 hours

- Dry Time Heavy Traffic: 24-48 hours

Choose options