Water Reducible Concentrated (WRC) Concrete Stain

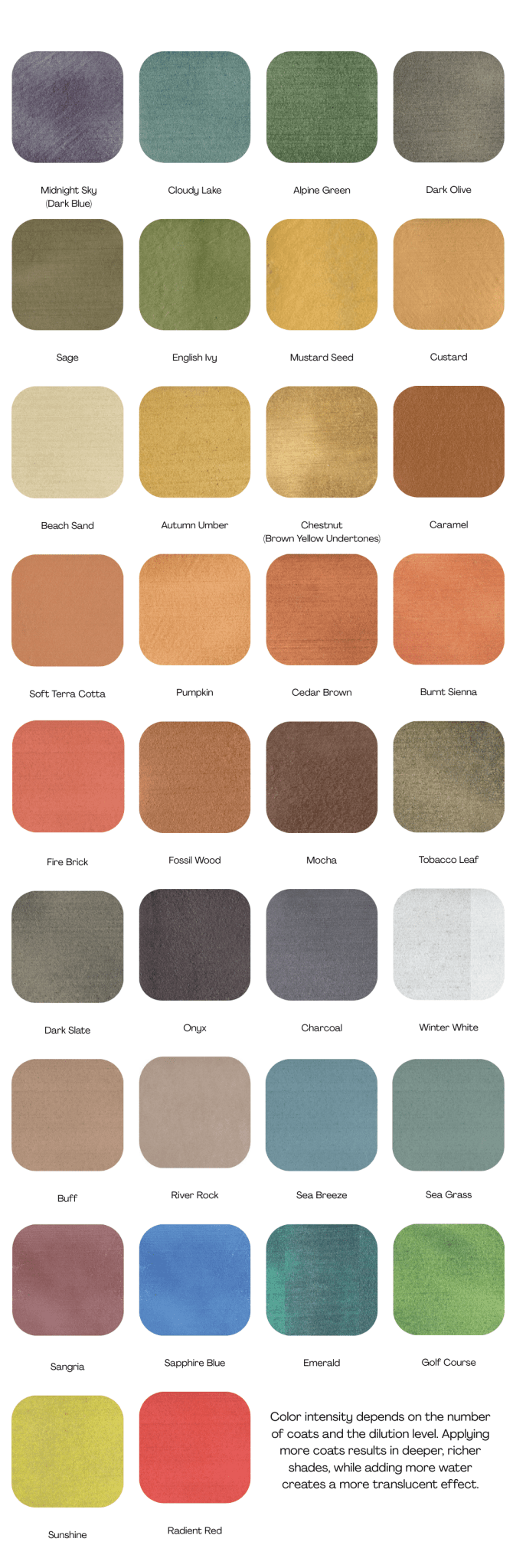

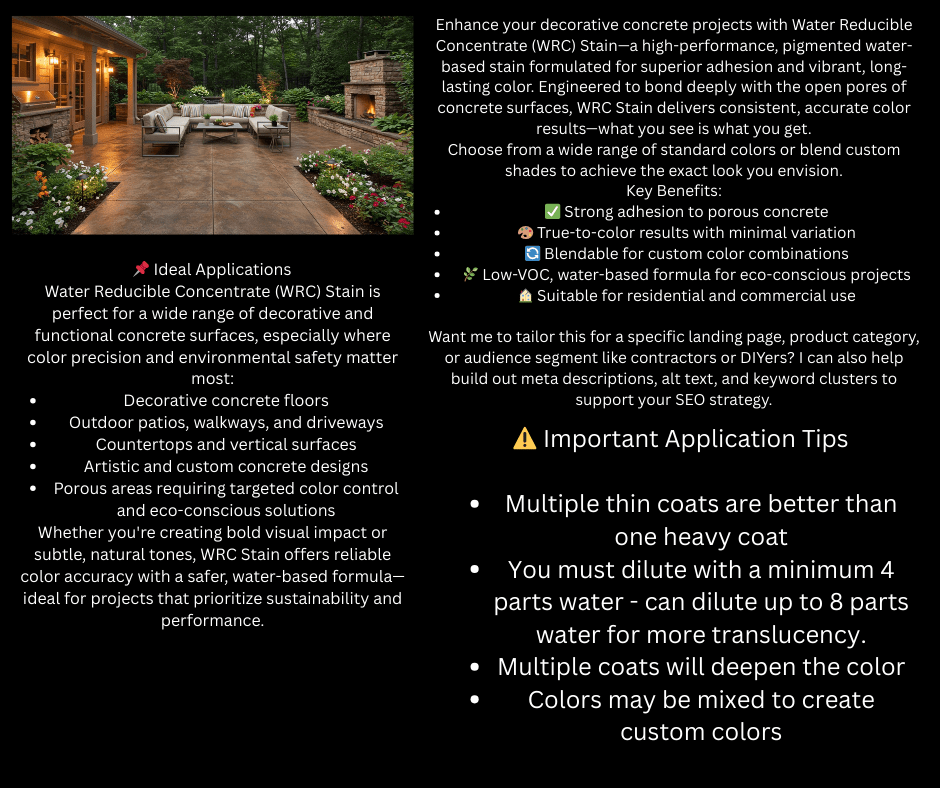

Water Reducible Concentrated (WRC) Concrete Stain transforms concrete surfaces with vibrant color accuracy and superior bonding. This pigmented waterborne stain penetrates open pores, delivering true-to-tone results—what you see is what you get. Its versatile formula allows for blending custom shades and creating unique color variations, making it perfect for decorative concrete projects of all kinds.

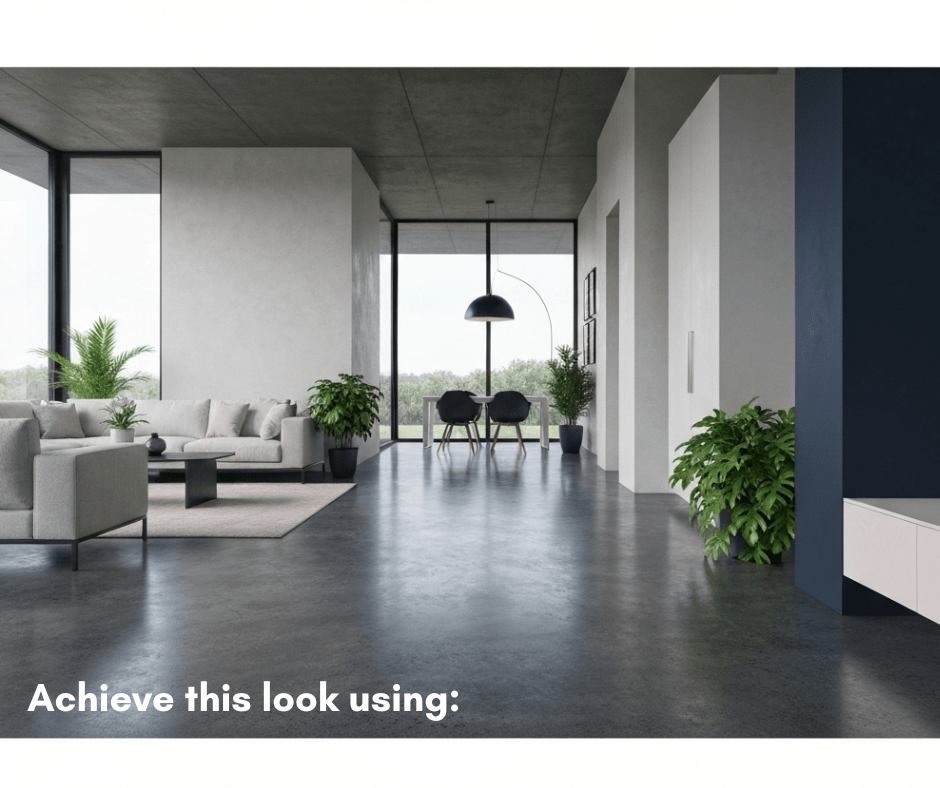

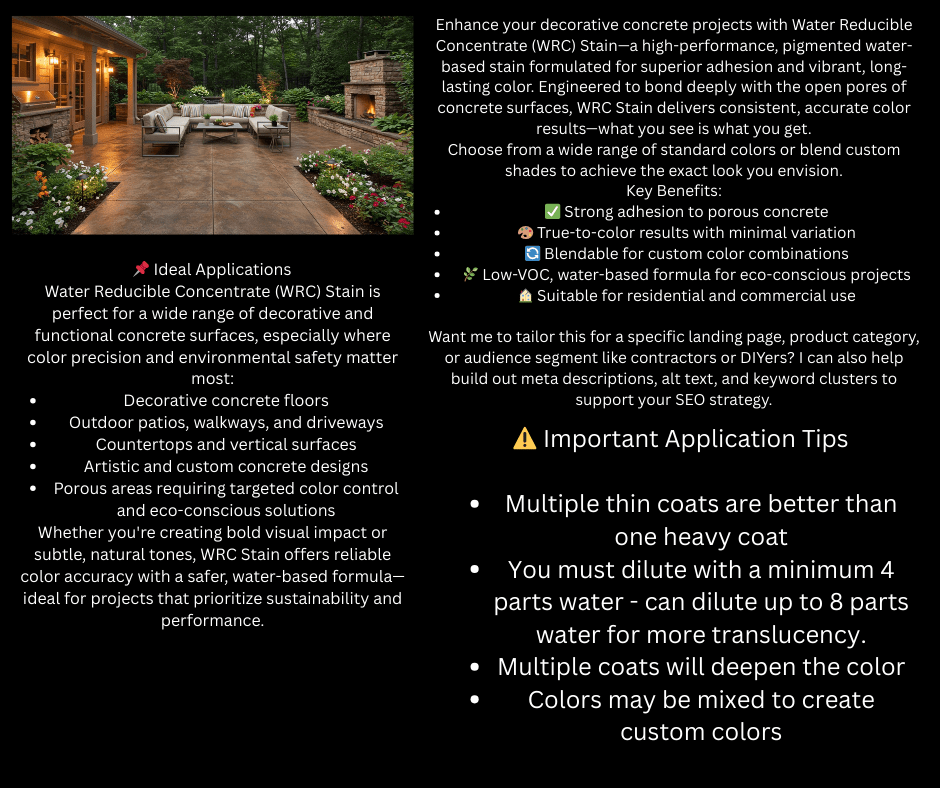

WRC Stain doesn’t just color concrete—it revitalizes it. Whether used indoors or outdoors, it provides a long-lasting, visually striking finish that enhances the character of any space. From patios and walkways to interior floors and feature walls, WRC Stain turns ordinary concrete into a dynamic canvas. Its adaptability and performance make it a go-to choice for professionals and DIYers alike.

Elevate your concrete design with a stain that’s innovative, reliable, and rich in color. WRC Stain is where precision meets creativity.

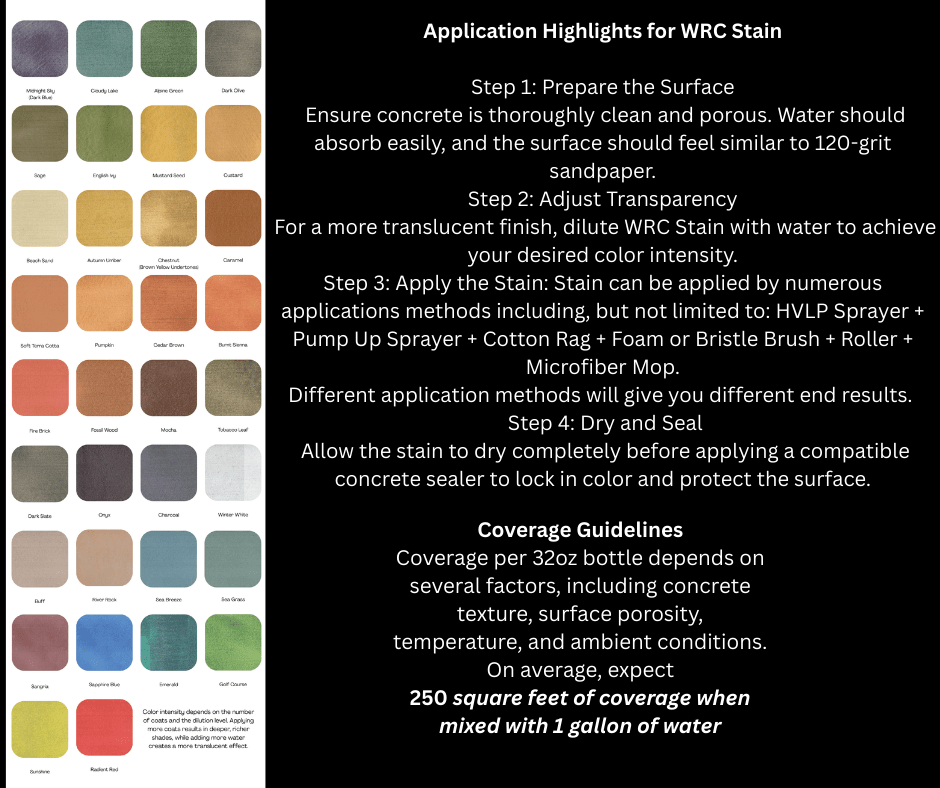

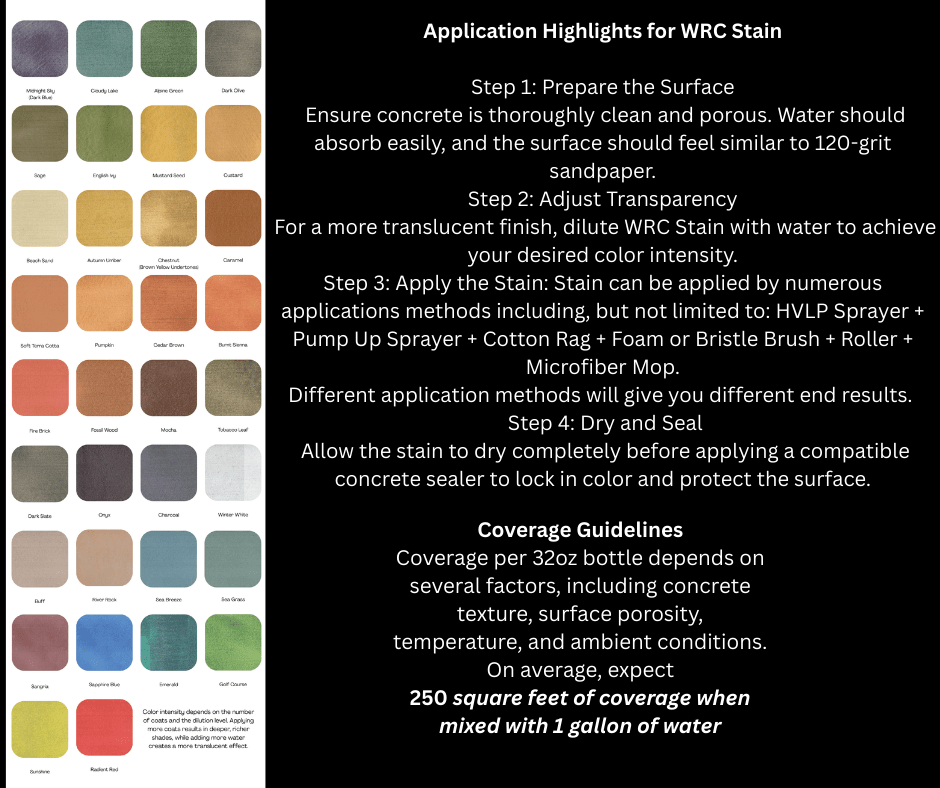

When utilizing WRC Stain, proper dilution is key. A minimum ratio of 4 parts water to 1 part stain allows a 32 oz bottle to yield an impressive 1.25 gallons of ready-to-use stain, covering up to 150 square feet. For those seeking a softer, more translucent finish, the stain can be diluted up to 8 parts water to 1 part stain, extending coverage to approximately 300 square feet. Multiple coats can be applied for a richer and more opaque color, catering to diverse aesthetic

preferences.

To ensure optimal results, diligent surface preparation is essential. The concrete must be impeccably clean and porous, allowing water to soak in and achieving a textured feel akin to 120 grit sandpaper.

Scratch test the concrete to verify the top surface is not dusting or disintegrating. Concrete must be clean and free of all dirt and contaminants. Concrete floors must be open and porous prior to applying WRC Stain. Approved materials for the cleaning and preparation process are as follows:

CR-580 Degreaser – Used for the removal of oil and grease.

CR-590 Paint & Sealer Remover – Used to remove paints and sealers.

CR-765 Surface Etch & Prep – Used for laitance removal and opening of pores of the concrete.

CR-585 Surface Neutralizer – Used to balance the surface pH after application of Surface Etch & Prep

Step 1: If needed remove all paint and/or sealer from the surface using CR-590 Paint & Sealer Remover

Step 2: If the surface has an oily or greasy film OR if CR-590 Paint & Sealer Remover was used, scrub the surface using CR-580 Degreaser.

Step 3: (REQUIRED IF WATER DOES NOT ABSORB INTO THE CONCRETE QUICKLY) Apply CR-765 Surface Etch & Prep at a dilution ratio of 4 parts water to 1 part Surface Etch & Prep scrub in with a stiff bristle broom. When the fizzing action stops, rinse the surface with water. Do not allow the Surface Etch & Prep solution to dry on the concrete. If a more porous surface is needed repeat Step 3, an interior floor’s surface texture should feel similar to 120 grit sand paper.

Step 4: (REQUIRED IF ETCHED) Apply CR-585 Surface Neutralizer (dilution of 8 oz in 5 gallons water) using a stiff bristle brush or broom to scrub in the neutralizing solution then rinse with water.

Step 5: (REQUIRED) Thoroughly scrub the surface. Interior floors require the use of a floor machine (buffer) with a black pad, sanding screen or coatings removal pad. Exterior concrete preparation requires the use of a pressure washer.

Step 6: After allowing the surface to dry apply WRC Stain.

Application- When spraying WRC Stain, protect surroundings with masking paper or masking plastic. Always use a filter when pouring the “ready to use” WRC Stain into a sprayer.

Tools that can be used for application of WRC Stain: gravity feed HVLP sprayer (preferred), pressure pot HVLP sprayer, airless sprayer, pump sprayer, cotton rag, natural sponge (sea sponge), manufactured sponge or brush (bristle or foam).

Concrete surface temperature must be between 50 -90 degrees.

In arid climates it may be necessary to dampen the concrete prior to application of stain to prevent the material from drying instantly. In order to penetrate the stain must have several minutes of “wet” time on the surface.

Drying Time– Drying time is dependent upon temperature and humidity.

Dry to touch / recoat 15 -30 minutes

Light foot traffic 1 hour

Clean Up– Tools can be cleaned with water and/or soapy water.

A minimum of 24 hours of drying time (after the stain has dried to the touch) is required before applying a clear sealer.

It is strongly recommended that a clear sealer be applied as a top coat for abrasion and UV resistance. It is recommended that a non-skid / skid reducer be utilized when sealing exterior surfaces.

Choose options

Achieve with dark olive wrc

Achieve with Mustard Seed WRC