I stained a section my patio. Here is photo of before and after staining -and after staining and sealing. This stuff was easy to use. Just follow the direction. The hardest part was getting the carpet glue off after removing the carpet. Finally had to rent a floor sander. Not bad for a 75 yr old woman and 48 yr old concrete

I saw beautiful pictures online but was skeptical if i could actually use it. It is super easy to use. This is NOT gel like, but very thin and watery. I was able to use a squeegie to move it around some though but had to move quickly to do that before it soaked in and dried. I did make some splashes but thats ok because we have to paint anyway. It is a good bit of product, but a little more pricey than other brands. It comes out yellow and gradually moves to a more rusty color. Blended beautifully with an acrylic paint mixture i made to create the green/blue color. I had quite a bit of stuck on glue left after removing old green carpet. I was hoping this might dye it a little but it doesn't so be aware of that. Excellent product! 5 out of 5. Am purchasing again to complete my entire hone & outdoor areas.

If you have a garage floor type concrete - this will work great for you. If you have the rougher drive way - not so good… I believe it even says that in the product…applied with a sponge and dabbed.Be sure to vacuum up once you apply neutralizer… it will stain the gutter. Thanksb

I used this on a polished concrete slab below a woodstove. I had to get a second color to achieve the exact look desired, but the final result is stunning. I wanted to pick up the colors of the natural stone wall behind the stove as well as some of the tone in the wood floor in the room. With a little experimenting I got exactly what I wanted. The result is a variegated natural looking effect that draws positive comments from visitors who often express complete surprise that it is actually concrete. The color has a lot of depth and changes subtly in different lighting, the effect is fantastic.This is a true stain, it can't be scratched off like a paint and the color is deep into the concrete. Directions were sparse but a quick call to the manufacturer found a company with friendly staff who were very happy to help and offer advice on using their products. Excellent service.Keep in mind that the actual concrete mix will have a large effect on the final color, so what you see in the picture may not be exactly what you wind up with. This is the nature of this type of stain and not negative comment on the product - just something to be aware of. The chemicals in the stain "react" with the concrete to give the color - a small variation in the mix or sand type etc. will change the final result - not that you will end up with blue when you ordered red - but the shading and tone may be different. You may need to experiment a bit to get what you want - but the end result is worth the effort.I used this and the "Mountain Road" color together - The colors by themselves have variations in their tones, but I blotted some extra of the two colors on in a few areas to vary the darkness a bit and give it a more visually interesting pattern.

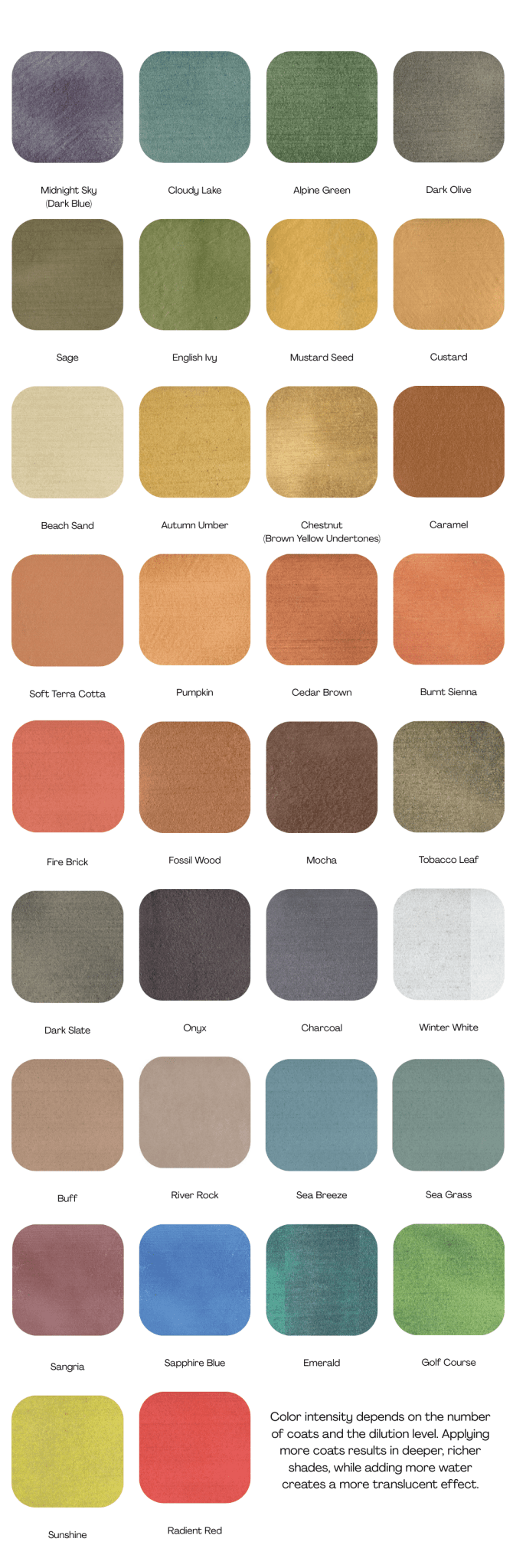

I purchased both black walnut and azure sky to use over an extremely light brown shade that I loathed and actually hoped would accentuate the grays. I love the mix of the colors! Diluted them both since I actually desired a light look (as I was initially hoping for gray) and was able to cover my 250sqft room for a reasonable price with these two whose colors were perfectly vibrant even being diluted 5:1 and 4:1 respectively. Would definitely by again! Wish I purchased these the first time! Especially since I had enough black walnut left over to have produced the initial effect 🙃.

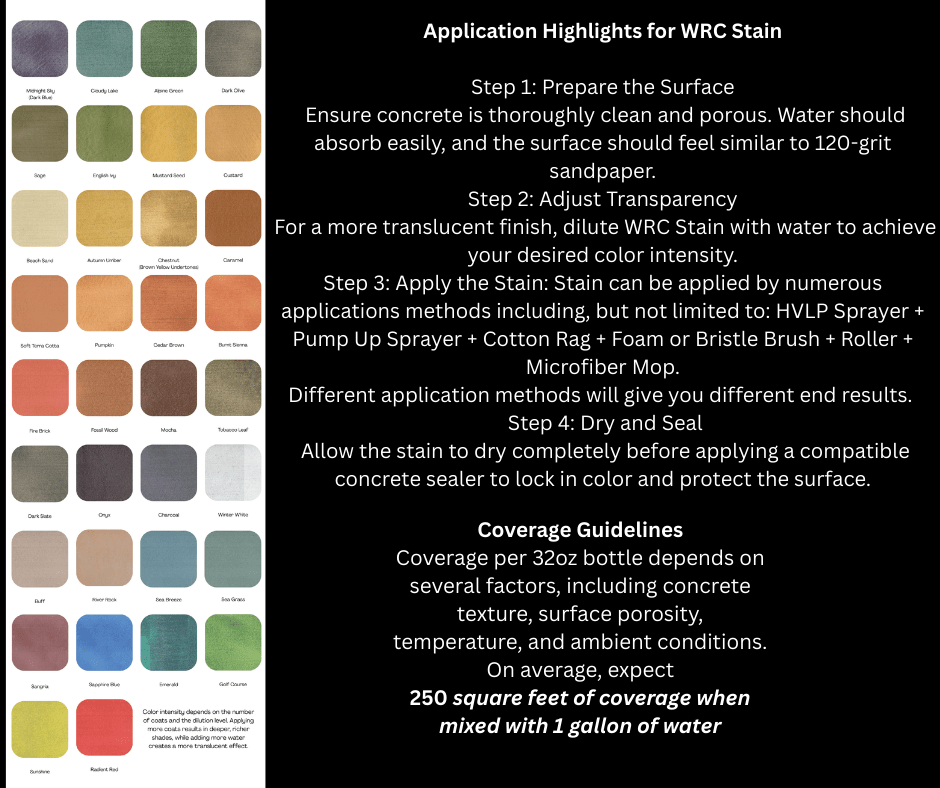

Trust the process. Half way through I thought it was going to turn out horrible. But it turned out great and we love it. I made sure our concrete was super clean and etched it before adding the stain. I sprayed mine in with a mixture of 3 parts water, 1 part stain. I applied 3 coats. After spraying the concrete with ammonia to level out the acid I scrubbed it again. Then applied a coat of sealant.

Black walnut, defiantly dark. If you're looking for dark brown almost black this is it. seems to continue working for hours after applying. results will be different on different types of concrete.

This is a great product if you like do-it-yourself projects. My wife and I were able to stain our new 1600 sq ft broomed concrete driveway in a day. We waited until the driveway was water cured and dried, about 3-4 weeks after pouring the concrete. Then we sprayed on, with a garden sprayer, a mixture of 1 part of Golden Sand and 2 parts of diluent CR-645. The driveway was neutralized with dilute ammonia after 1-2 hours and then washed off with a hose. After a few days the driveway was sealed by us by spraying on a DoT-approved silicate concrete sealer. And viola: the result was beautiful and water repellent, and we saved thousands of dollars doing it ourselves.

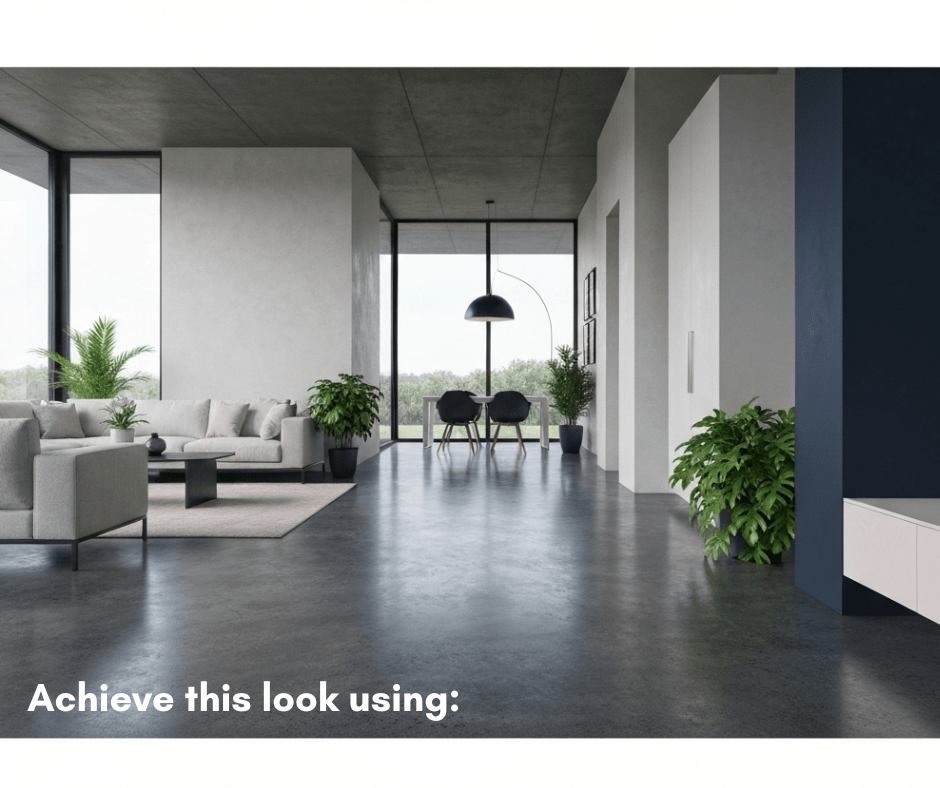

I had a new pool installed and the concrete contractor really really messed up. I can’t even explain how bad it was or what happened, but you can see the before photos I’ve attached(ones that look terrible) and yup that was a brand new slab 1100sq ft on a brand new house. So after negotiating some money back, <- I know I’m crazy I should have had him rip it out, but to save you the details I didn’t. I first had to strip the existing sealer(I did this with bed sheets and xylene). It’s important to make sure the concrete doesn’t have any sealer remaining. You can also etch the concrete to open the poors too but I do not. After this I wanted a specific gray so I experimented with all kinds of antique’s and stains. It was really hard to find a stain that didn’t include a sealer in it so after about a month of experimenting with different Behr gray stain from Home Depot( was alway too blue) I came across this company on amazon. I read some reviews and decided to buy a small bottle of white and charcoal. As soon as it came in I began experimenting. First try was too light, second try too dark, then after sleeping on it, i tried again and came up with a good color that I liked. ( start with a white base and add small amounts of charcoal until you get it. Then test it on a small piece of concrete. A little charcoal goes a long way. It is important to use small amounts or you will rip through your bottles quickly during your tests. So I ended up using the caps of the bottles for my measuring(micro level). Ultimately I ended up with 1 part white, 3/4 parts charcoal and 4 parts distilled water. This created an almost solid stain in a decent medium gray. I then sprayed it on with a cone tip sprayer, then applied a second coat. Unfortunately it rained right after but the stain was dry so It stuck. The next day, I applied liberally Brickform Antique-it in dark gray over top with a soft bristle brush. <- this gives it a natural aged realistic stone highlight look. I waited 2 hours then applied two light coats of diamond clear sealer by Euclid( commercial grade sealer) I ended up contacting the company directly instead of buying my bottles from amazon because they sell a 32oz bottle and if you buy 8 or more there is a discount. I needed about 8 32oz bottles for my project. It’s kind of expensive but the alternative to have a company come in and do it would have been way more. Oh yeah here’s a tip. Use a paint brush for your testing instead of sprayer. I’d recommend this product as it turned out great. It was easy to use, shipping was quick and they have some really awesome colors. The only thing is you really have to seal it in or it will probably wipe off on traffic areas. Even though it says penetrating, in my experience it did penetrate the concrete but I could still wipe some of it(top layer) off with a really hard scrub. <- I should have etched it and probably wouldn't have had this. Oh yeah another tip. Have some xylene and scrub brush handy while you are testing. It will pull it off. Anyway. Hope this helps someone.

Update::So I originally stained and sealed this in October. It went through a harsh buffalo winter and pretty much still looks great. However I did notice some small areas scattered around where the stain had come off a little. Almost looks like the concrete didn’t absorb it quite right or maybe it is that it was a new slab of concrete and hadn’t settled yet. I also did a very light coat of sealer so maybe that’s why too. The spots look like small scratches or blotches no bigger than a dime(some smaller) the rest of it still looks amazing and is very durable with the sealer I used. I’m going to touch it up with a paint brush and re-reseal. Still 5 stars.

I bought a selection of colors and was able to mix it to perfectly match a 6”x6” patch and two larger patches about 4”x12” that I did on exposed aggregate by staining the concrete itself (dabbed on the surface NOT mixed into concrete) but also by staining individual rocks in the pea gravel so it looks like the same color mix as used in a 1911 house. The patch is not noticeable to a casual observer. Expensive, but worth it to save the look of my house! Be aware that it seals concrete so on a rainy day a patch stands out next to wet concrete. It’s a compromise i can live with.

So this product is great and so easy to use. Just find your color or mix two colors together and then add 4 parts water to one part color with distilled water in the empty gallon jug, then shake well. It goes on no different than painting a surface with very watery paint. Either use a small nap soft paint roller to make nice smooth applications and a foam brush for your edges and corners, or use a pump sprayer if you've had good practice using that application.

Unfortunately, I thought the color Charcoal was pre mixed black and white because I wanted a grey patio and I wanted to coat over the different ages of concrete, old, new and repair jobs. My goal was to make everything uniform and look newer and all solid grey. In reality, Charcoal is a mix of black, white, and blue. I mixed the Charcoal with white to lighten it up so I could use several coats without it getting so dark. Unfortunately, I didn't realize Charcoal has a blue base, so when I was done, the color ended up drying grey with a decent amount of blue. It looked exactly like the color of Honda's Sonic Gray Pearl, which if you look up, is a grey blue.

I now ordered black so I can mix with white to get the grey I originally wanted. I'm just not sure if I'm going to be able to change the color after two coats of the charcoal turning it blue. So in short, the product is great, but be careful with the colors, or get the 8oz first and mix with 4 parts water and paint some strips of cardboard, paper, brick, etc, so you can see how the color dries. You may need to mix other colors or swap our colors until you get what you want.

Also make sure you get 16 oz paint measuring cups so you can measure exactly how much of your color of combination of colors and then so you can add that up and multiple by 4 so you know how much distilled water to use.

Good luck applying, but be prepared to use 3 coats to ensure you have smooth, even coverage without any uneven base shades from showing through. The second and third coats will go on significantly faster and use a lot less product, but you still want to put it on semi-thick so any areas that don't absorb as well end up with a uniform color.

This was my first brick staining project and it was very easy to use. I brushed on a couple of coats over faded red brick and sealed it with a product from a big box. Easy project!

I would say this product works great.

The uneven distribution gives it the beauty and natural look

I like the product! I covers better then what it stated. I used 3 1/2 bottles when it called for 7. The only negative was i gad to pay $42 to return the bottles even though I purchased it threw Amazon Prime. I emailed to company abd they told me they would wave the restocking fee. There was nothing about a resticking fee. Product is great, company bot so great.

Acid stain was easy to use, went on smoothly and evenly with a plastic weed sprayer bottle and then rolled over with a 9" wide x3/8" nap roller. Color is great as it was applied to a fresh thin layer of hydraulic cement. Covered a 9' x 25' floor with about 2 cups remaining.

Water based concrete stain for rock waterfall. Good quality.

Color shown is a bit misleading. When used on white concrete, results are way more blue than the blue green/aqua/turquoise color shown. In fact it has practically no noticeable green tone at all. Assuming the sample shown was done on a warm toned, gray-brown concrete sample. Even still I'm not sure how they got so much green, mine is a bright sky blue - exactly what the product is named - go figure.However the stain works great and quite fast, even diluted.

Be very careful with this stuff. I really like it but it is dark. I should've cut it down more for the look I wanted. I think the key is to keep the surface misted with water while applying. I forgot to do so and it turned out darker than I wanted. It still looks great, but not what I was trying to achieve. Seal it good with a medium sheen sealer and it looks great.